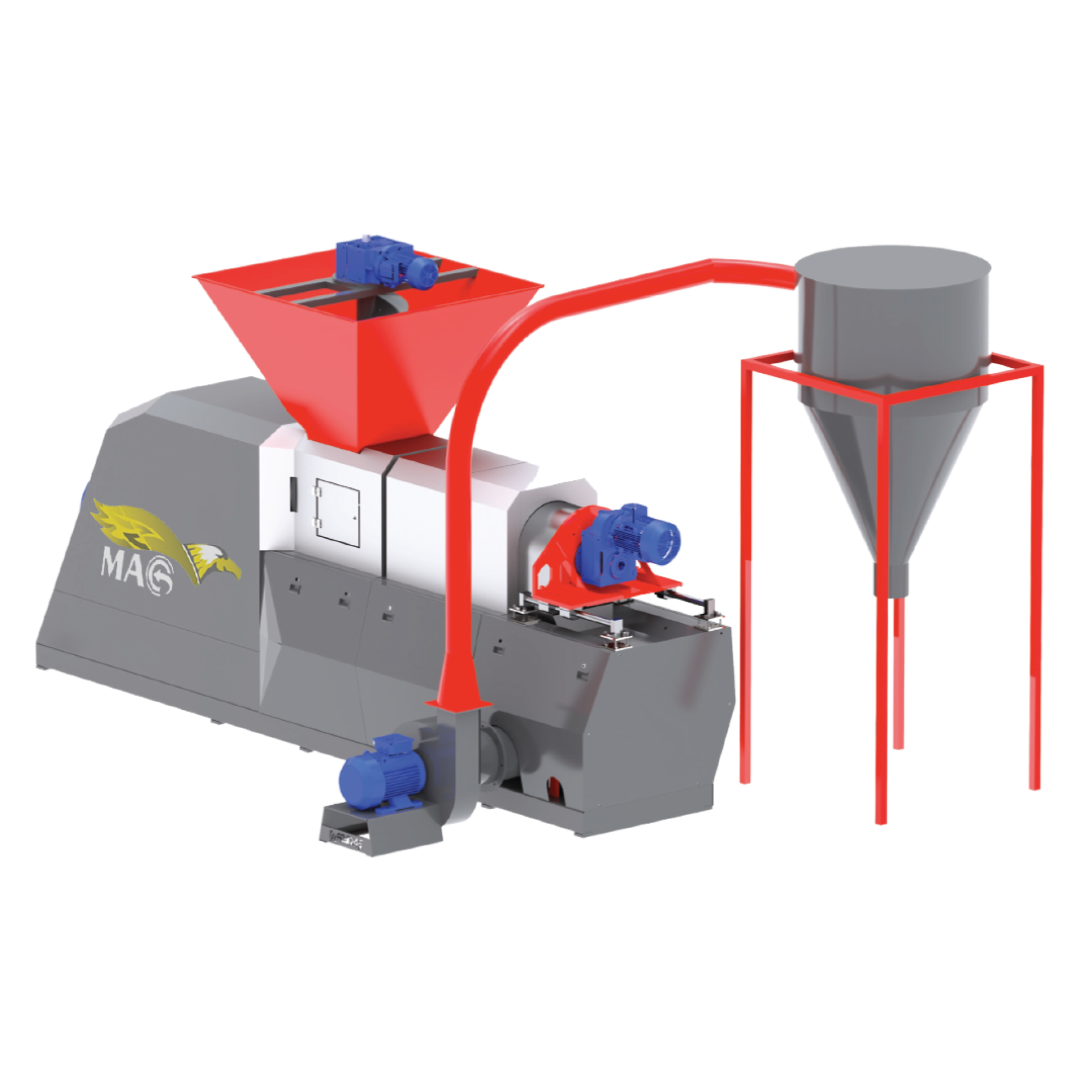

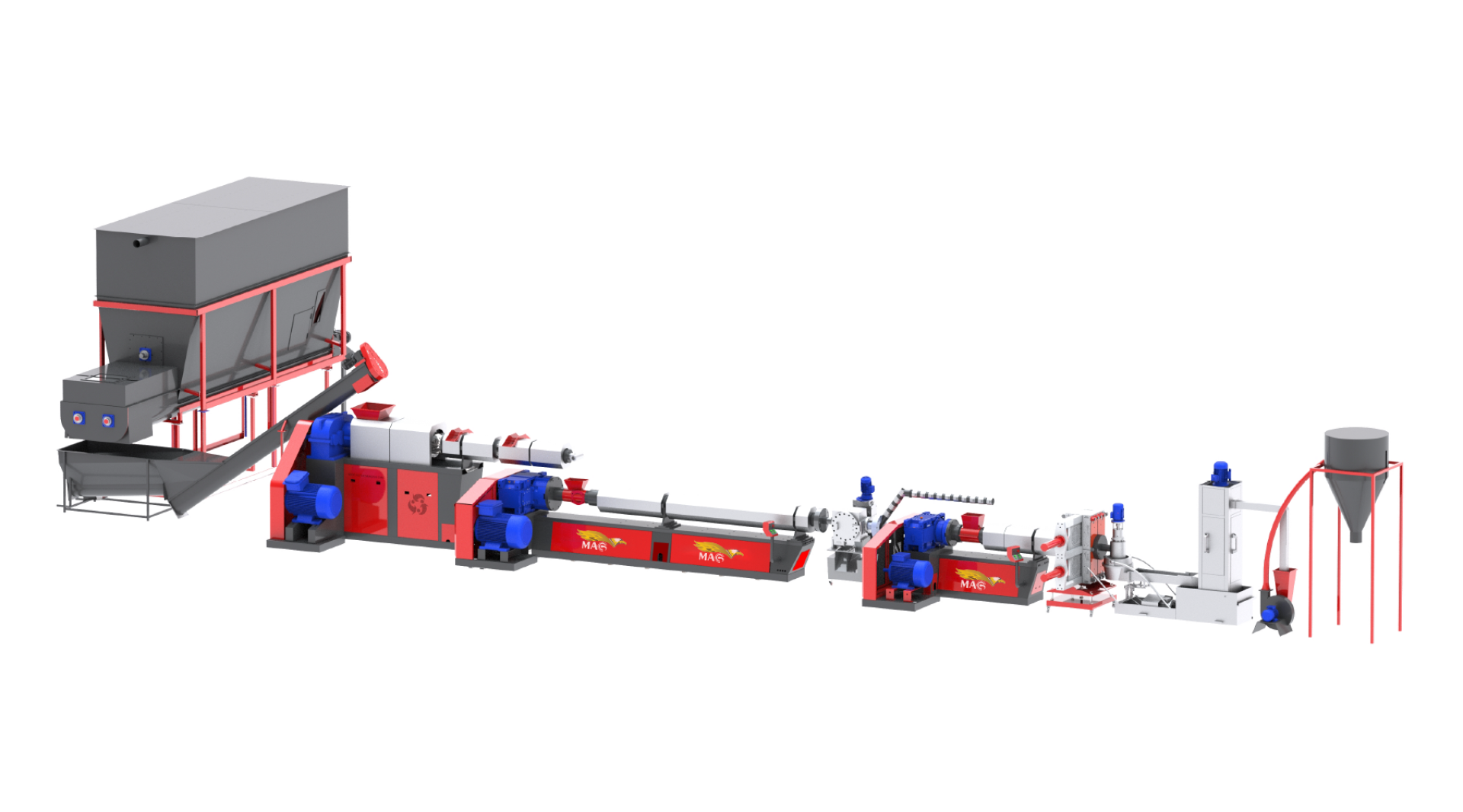

It is observed that the materials processed with the Triple Compact Granule Machine, which emerged as a result of the R&D, maintain the color quality and the product obtained in transparent crushing is also of the same transparency. Fish eye and homogeneous dispersion problems are not observed in the materials processed from the granules coming out of the triple compact Granule Machine. In addition, the problem of clogging the filters with the products such as paper, PVC and PET is eliminated and the best quality granules are obtained.

Fisheye occurs due to the presence of gaseous products or excessive heating of the product. Such a situation does not occur with the Triple Compact Granule Machine.

Since the shredding process does not take place, the situation where the products such as paper, PVC, pet become microplastic in the agglomer and clog the filters is not observed in this machine.

It provides homogeneous kneading of the plastic product. In this way, unmelted material residues do not form on the film surfaces.

The combustion and discoloration are observed in granules coming out of the old generation recycling machines. Additionally, while fisheye and non-homogeneous dispersion problem will be observed in products made from this granule, filter clogging problem will be observed in the machines produced for the final product.

This machine has a great importance in reducing the remaining 8%-12% moisture content after Horizontal Squeezing of PE and PP film products cleaned in the washing line to 0%.

- It reduces the electricity consumption by 30%.

- It minimizes the workforce.

- It ensures maximum energy efficiency by sending the squeezed and heated product to the main extruder without loss of energy.

- Contrary to agglomerated systems, this system has low electricity consumption.

- Unit energy consumption costs are lower.

- A very clean granule raw material is obtained as the product is filtered twice and processed twice.

- This system does not consume high electricity, as the other agglomeration systems and does not need much heat that would be supplied by the heater.

- Since all of the PE-PP film materials are kneaded very well thanks to this Triple Compact Extruder, they have a more homogeneous structure.

- Thanks to the special design of the whole system, there are no air bubbles in the raw material.

| Triple Compact Extruder System - Machine Details | ||||

| Machine Details | Compactor 200 | Compactor 300 | Compactor 500 | |

| Screw Dıametre |

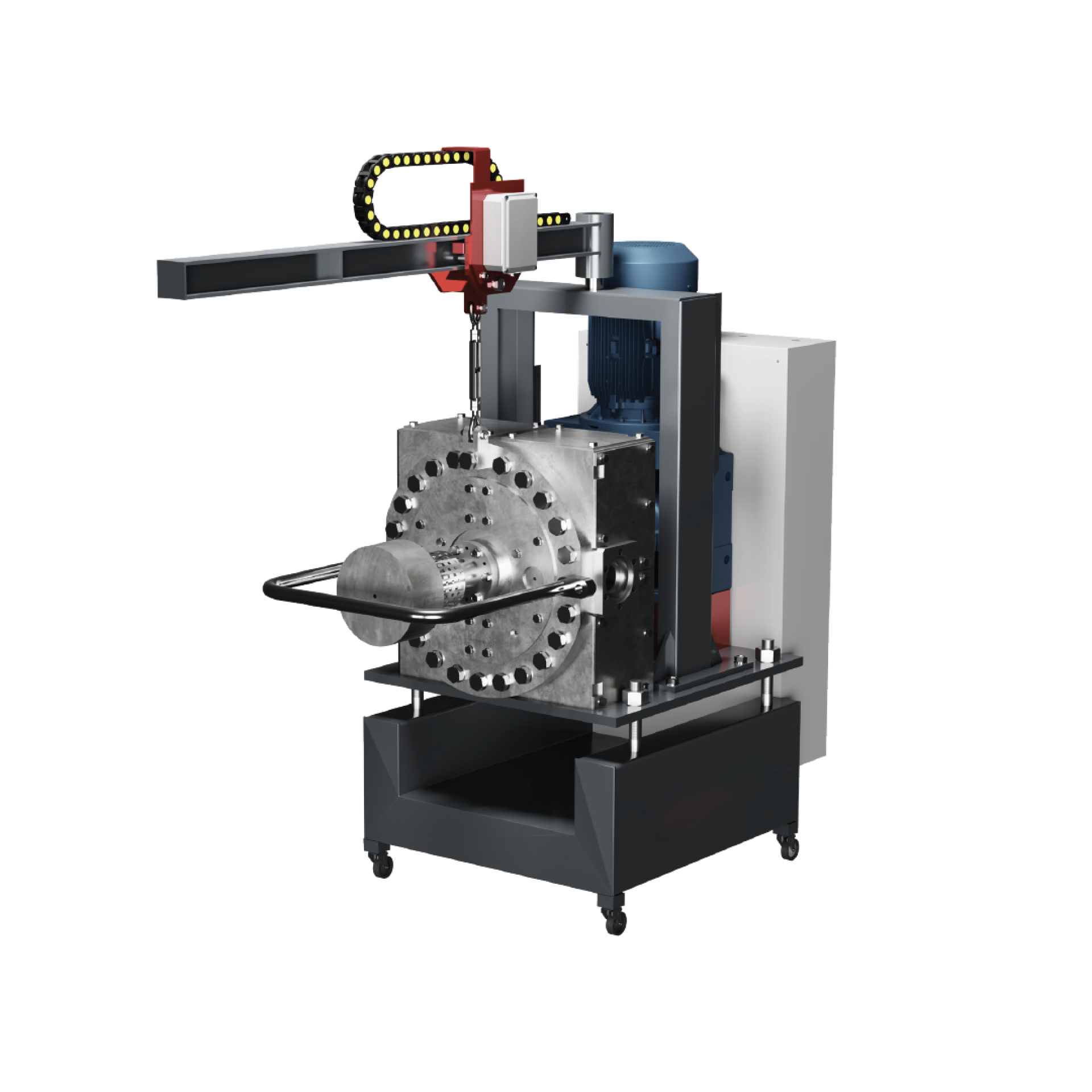

1. COMPACT EXTRUDER 2. GRANULE EXTRUDER 3. CO-EXTRUDER |

200 MM 120 MM 150 MM |

300 MM 150 MM 170 MM |

500 MM 160 MM 200 MM |

| Filter Dıametre |

1. COMPACT EXTRUDER 2. GRANULE EXTRUDER 3. CO-EXTRUDER |

- 250 MM Single 250 MM Single |

- 400 MM Auto 330 MM Single |

- 400 MM Auto 330 MM Single |

| Machine Length |

1. COMPACT EXTRUDER 2. GRANULE EXTRUDER 3. CO-EXTRUDER |

3300 MM 6500 MM 3000 MM |

4000 MM 7500 MM 3500 MM |

5500 MM 8500 MM 4000 MM |

| Raw Material Input Humidty |

1. COMPACT EXTRUDER 2. GRANULE EXTRUDER 3. CO-EXTRUDER |

%8 - 12 %0- 3 %0 |

%8 - 12 %0- 3 %0 |

%8 - 12 %0- 3 %0 |

| Motor Power |

1. COMPACT EXTRUDER 2. GRANULE EXTRUDER 3. CO-EXTRUDER |

55 KW 75 KW 45 KW |

110 KW 160 KW 55 KW |

132 KW 200 KW 75 KW |

| Capacity |

- | 200-300 kg /h | 600-700 kg /h | 700-1000 kg /h |

No catalog found for this product