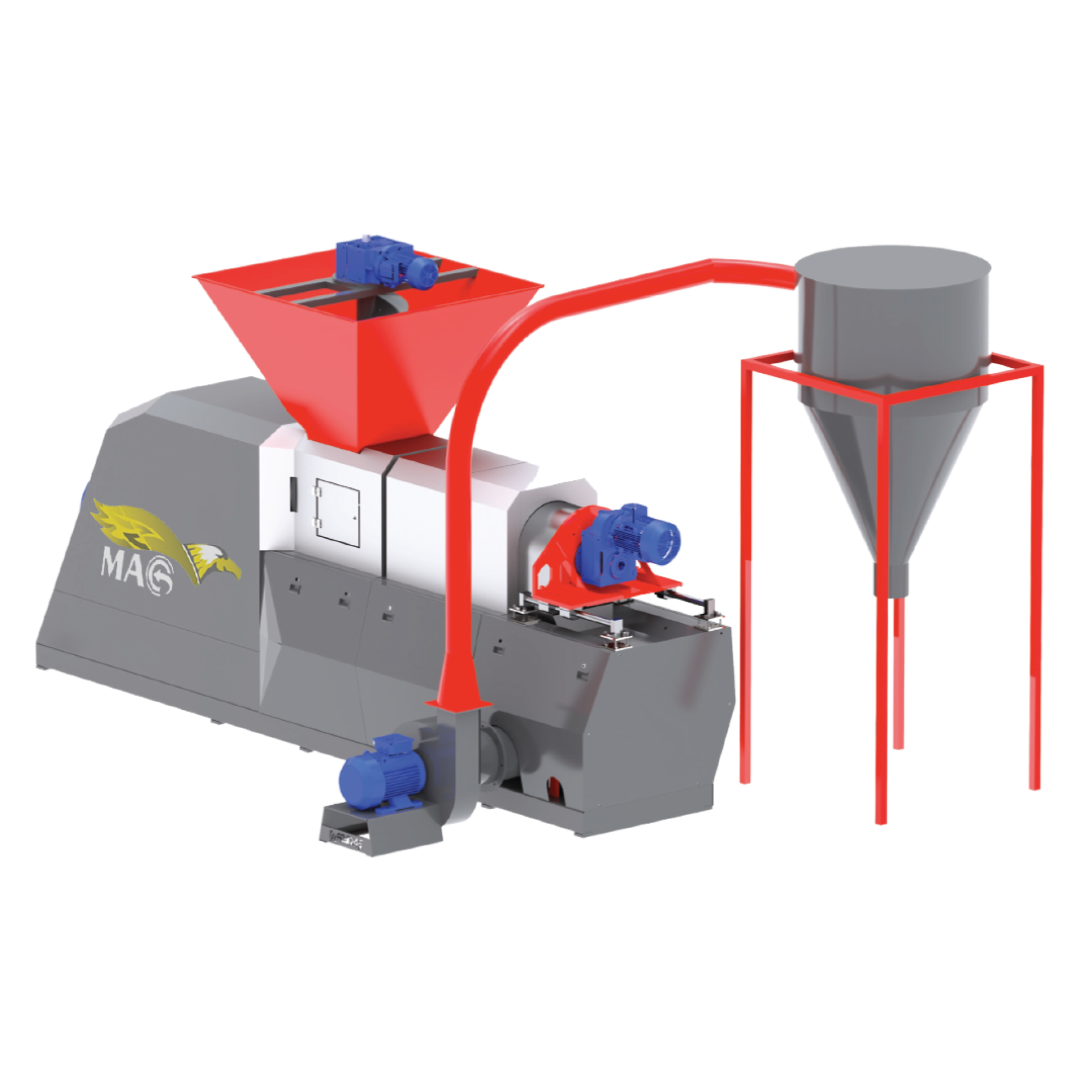

GRANULE MACHINE

The Granule Machine enables the recycling of waste plastic It is the last stage of raw material formation The screw geometry of the Granule Machine is produced with superior technologies according to the material it processes This makes the Granule Machine highly performing and durable Granule Machine is the most important part of the recycling line This recycling line can optionally be controlled by computer or manually This system minimizes the chance of operators to make mistakes The working logic of the Granule Machine is as follows The raw materials extracted from the agglomeration are melted in the extruder and thrown out with the force of pressure and cut into granules by means of the sieve Thanks to the water cooling mechanism collected granules get cooled and with the assistance of silos they are filled in the bigbag sacks It is the most important stage of producing useful products for human use by preventing the produced granules from causing harm to the environment by recycling them repeatedly

| Granule Machine DRAGON Machine Details | |||||

| MODEL NO | Shaft Diameter and Length | Filter Diameter | Machine Length | Machine Width | Machine Width |

| Dragon 120 | 120*4000 mm | 200 mm | 5750 mm | 2140 mm | 2900 mm |

| Dragon 130 | 130*4500 mm | 250 mm | 6250 mm | 2143 mm | 2918 mm |

| Dragon 140 |

140*5000 mm | 330 mm | 7500 mm | 2250 mm | 3100 mm |

| Dragon 150 |

150*5500 mm | 330 mm | 7500 mm | 2250 mm | 3100 mm |

| Dragon 160 |

160*6000 mm | 330 mm - Çift | 8000 mm | 2320 mm | 3100 mm |

No catalog found for this product

| Granule Machine DRAGON Engine System Details | |||

| MODEL NO | Motor power | Total power | Capacity |

| Dragon 120 | 55 kw | 105 kw | 200-250 kg/h |

| Dragon 130 | 75 kw | 135 kw | 250-350 kg/h |

| Dragon 140 | 110 kw | 150 kw | 350-450 kg/h |

| Dragon 150 | 132 kw | 180 kw | 400-500 kg/h |

| Dragon 160 | 160 kw | 200 kw | 500-600 kg/h |

| Dragon 180 | 250 kw | 465 kw | 700-1000 kg/h |